Research Article - European Journal of Applied Engineering and Scientific Research ( 2018) Volume 6, Issue 3

The purpose of this paper is to design an artificial incubator whose costs would be around 353.54 USD, using simple technology accessible to communities. In fact, during a field trip to the NGO ORFED, we noticed that the poultry farmers are facing a problem concerning the real needs in terms of acquiring day-old chicks. Although CAMEROON's major concern with poultry production is to reduce the massive importation of poultry products such as frozen chicken, there are serious problems in keeping pace with market demand (very low supply); low production favored by factors such as the cost of acquisition of the high chick, the scarcity and unavailability of chicks on the market. Following the fact that the production of chicks was done by hand and with a very low yield, we present an approach which consists in making a synthesis of the different incubators that can be accessed; design a model of adapted equipment; size and choose the elements of our incubator.

Brooding; Design; Dimensioning; Egg; Incubator; Model

The Cameroon market is experiencing a steady rise in the price of farmed products: broiler chicken, eggs, pork, beef. This price increase is mainly orchestrated and sustained by an inability to follow the demand of the markets, therefore the insufficiency of the production. This lack of production is created and supported by several factors among which is the lack of production equipment such as incubators.

In this study, we will focus particularly on the production of chicks. This approach fits in perfectly with the policy pursued by the Cameroonian government to fight against poverty.

Driven by the exorbitant cost of chicks on the market and driven by the particular concern of technology transfer, the ORFED NGO funded by French cooperation, whose main objective is the development of the rural world, offers important assistance to livestock farmers. It's in this perspective that we have been proposed to design and build an incubator that can incubate nearly 300 eggs, in order to boost chick production, including the revaluation of Cameroonian poultry farming; because in the field the incubators encountered were of small capacity (100 to 150 eggs) and having poor yields (approximately 55%).

Literature related work on brooding

In subsistence farms, eggs are incubated most of the time using broody hens. In commercial farms, artificial incubation with incubators can be used. The choice will depend on the number of chicks that one wishes to breed at the same time. To ensure the success of an important breeding, all the chicks must leave at the same time. This is difficult to achieve naturally because the hens do not all incubate during the same period. The poultry farmer can then consider the purchase of a small incubator, possibly jointly with other chicken farmers.

Natural incubation: The term brooding covers two complementary aspects of the parental behavior of birds: incubation and youth care. In wild birds, brooding occurs systematically after the production of a certain number of eggs and goes hand in hand with the cessation of oviposition: it is therefore closely related to the ovulation function and must be considered as the point culminating cycle of reproduction [1].

Brooding in the hen is usually done during the rainy season. This would be related to the fact that the chicken egg being incubated needs a lot of moisture [2,3]. Various behaviors characterize the brooding phase: nest maintenance, overturning of eggs, swelling of feathers and aggressive posture during an approach, emission of special vocalises and above all, sitting on the nest; a hen can spend 90% of her time on her nest, leaving it only briefly (10 to 15 minutes) to eat and drink. The quantity of food that it ingests is very small and its body weight can decrease by 1 kg [1]. A hen is able to hatch 8 to 10 eggs, which will give about 6 to 7 chicks.

Brooding up to 23 days, the chicken lays at best 1 egg per day. She will begin to hatch its eggs after a period of about ten days, for an average of 21 days. But the mortality rate of chicks is often very high. The experience gained and the ability of the farmer to reduce losses will help determine the number of hens he will need. The hatching rate varies from 60 to 80% with an average of 75% [4]. This hatching rate and the viability of the chicks are improved by a manganese level higher than 54 mg/kg of food [3].

Artificial Incubation: Artificial incubation is only a technique of substitution of the natural incubator which is the broody hen, by an equipment. Small brooders are commercially available which can incubate a large number of eggs at the same time. You can build one yourself with relatively simple means. Artificial incubation is performed using devices called incubators. According to Savadogo [3], the artificial incubator or incubator is a closed chamber in which the temperature, the humidity and the renewal of the air are maintained.

There are some artificial incubation techniques that include:

The collection and selection of eggs: Each collected egg must be examined separately and selected on the basis of:

• Weight: to hope for a good hatching rate you need a minimum of 45 g. Eliminate small eggs (weighing <45 g) as well as large eggs that may contain two yolks that may not hatch.

• The color of the eggs: selection according to the color of the eggs of the race (white or brown ...) and keep those of uniform colors.

• Shell: remove stained, thin and porous shell eggs, broken or scratched.

• Cleanliness of the eggs: too much dirt in the pores prevent ventilation. Clean with a slightly damp cloth if the egg is not too soiled. However, avoid washing the eggs at the risk of weakening them because the water could dissolve part of the shell.

• Age: It takes eggs of 5-10 days at least. Mirage distinguishes fresh eggs (reduced air chamber) from older eggs (larger air chamber) [5]. There are some artificial incubation techniques that include:

Cleaning and disinfection of hatching eggs: Disinfection of eggs should be done immediately after collection to avoid transcoquillous contamination at the time of oviposition or in the first minutes after laying [6]. In fact, the shell of the egg is porous; it lets air, water, dirt, and bacteria pass. Therefore, avoid taking risks by choosing to incubate only clean eggs. Clean slightly soiled eggs with a clean, dry cloth, but never excessively dirty eggs, and never wash the eggs with water. Water opens the pores of the shell, which: weakens the incubation results [7]. Abga [5] proposes in his study a disinfection of eggs with 1% permanganate.

Adjustment of incubation temperature and humidity: The incubator is turned on at least 1 hour before loading the eggs to allow for various adjustments (adjustments) of the temperature to 37.7°C.

The position of the eggs and their reversals in the incubator: The egg of the hen must, during the incubation phase, imperatively be placed "tip down". Otherwise, the orientation of the head to the inner tube is hurt and many chicks whose head is oriented towards the small end of the egg (opposite the inner tube) die.

The ventilation and mirage of eggs in incubation: The eggshell has many small holes (pores). These many pores are channels of exchange between the egg and its external environment. Thus enclosing eggs in a closed enclosure against any aeration, consists in killing the embryos by asphyxiation. Hence the renewal of air by a ventilation system in artificial incubators. Indeed, according to, one of the main technical parameters to be monitored throughout the incubation and hatching of egg storage process is the O2 and CO2 content. An egg needs to breathe.

Literature related work on design methods

According to the French Association of Standardization (AFNOR), the design is "the creative activity which, starting from the needs expressed and the existing knowledge, leads to the definition of a product satisfying these needs and industrially feasible".

The design can be classified into three types. According to the French Association of Standardization (AFNOR), the design is "the creative activity which, starting from the needs expressed and the existing knowledge, leads to the definition of a product satisfying these needs and industrially feasible".

• innovative design where we do not rely on the existing;

• the routine design where we start from a prototype that we improve;

• similarity-based design based on an existing object or phenomenon

This latter form of design is that which is employed and developed in the rest of this work. From the design methods that exist, we have:

Value analysis: According to AFNOR, it is a method of competitiveness, organized and creative, aimed at satisfying the needs of the user, through a specific design approach, which is functional, economical and multidisciplinary. In this analysis, the judgment criterion is the value of the product, which is a quantity that increases when the user's satisfaction increases or the expense inherent in the product decreases. The value can, therefore, be considered as the ratio between functional ability divided by the cost of solutions.

Quality Function Deployment (QFD): QFD is defined as a comprehensive and organized design methodology designed to understand and integrate the customer's voice throughout product development, from product design to delivery. One of the founders of the method, de fi nes Quality Function Deployment as a methodology that converts user demands into quality characteristics, determines the design quality of the finished product, and systematically deploys this (global) quality at the (local) level of the quality of components and processes, and their interrelationships [8]. It allows developing step by step and in detail each function or operation, in particular, those delicate from the point of view of quality, in order to systematically connect the objectives and the means to reach them.

Technically, the departure of the method is based on customer expectations (the "WHAT") as input parameters, related to the parameters of design and manufacturing (the "HOW") [9]. The whole method is based on a series of four matrices for organizing and correlating information. These matrices are generally called "houses" because of their shape.

Functional analysis: Although it is widely accepted as a tool for other design methods, functional analysis is a method in its own right that integrates the need that will highlight the product's services; the technique used to find the technical solutions of the needs of the product and the topological analysis which lays the groundwork for the spatial arrangement of the elements of the future product.

Phases of functional analysis

The phases of the functional analysis are given opposite (Figure 1).

Functional analysis of the need: According to AFNOR, a function is defined as the set of actions of a product or one of its constituents expressed exclusively in terms of purpose; while a need is a need or desire experienced by a user. According to AFNOR, functional specifications (CdCF) is a document by which the applicant expresses his need (or the one he is responsible for translating in terms of service functions and constraints), for each of which are defined criteria for the assessment and Each of its levels must have flexibility.

Technical-functional analysis: This enables the design to be analyzed from the technical point of view, ie the constitution, organization and internal functioning of the system or product, in order to fulfill the service functions. A technical function, according to the AFNOR, is an action internal to the product (between its constituents) defined by the designer-developer, within the framework of a solution, to ensure the service functions. A service function can correspond to a chain of technical functions. A service function is an action expected of the product (or carried out by it) to meet the need of a given user (AFNOR). Technical-functional decomposition helps the designer to better understand the problem, facilitates the search for principles and solutions, turning a global problem into smaller, easier-to-treat subsidiary problems for which solutions exist or can easily be invented.

Analysis tool of the need: the FAST diagram

For a given technological solution, the FAST diagram makes it possible to synthetically represent a hierarchical sequence of technical functions. From a given function, it is established by answering the questions: Why? When? How? Why? this question concerns the previous function. The answer begins with << For >>.

When? This question applies to one or more functions located at the same level. The answer starts with "Si simultaneously".

How? This question is for the following function. The answer begins with << In >>. Figure 2 below shows the principle of a FAST.

The FAST diagram then constitutes a set of essential data making it possible to have a good knowledge of a complex product and thus to be able to improve the proposed solution. As a result, it gives the constituent equipment of the product.

To carry out this work, we needed an egg as material and for the design process, we adopted the functional analysis.

Functional analysis

Functional analysis helps to structure the search for customer satisfaction by representing the product from the point of view of "service rendered", and encourages creativity by leaving open the choice of technical solutions [10].

Functional analysis of the need

The functional analysis of the need for a product, system or service is based on the principle that this product, system or service is valuable only by the benefits it brings to actors who expect something from it. It aims to maximize the quality of the product by focusing on the need it meets and the functions it fulfills.

Statement of need: To state the need is to express the fundamental requirement that justifies the design of the system. This approach is based on the dematerialization of the system that is to say on the exclusive consideration of the satisfactions it offers in order to fill the latent need of the applicant. For that, one is led to ask the three essential questions namely:

• At Who, at what does the system serve?

• On Who, on What is he operating on?

• For what purpose?

The graphical tool, called "horned beast" is shown schematically in Figure 3 below.

Functional specifications: The designer to develop the most efficient product, must take into account the expectations of the customer, usually expressed in terms of service functions in a document called Functional Specifications (CdCF). We have developed it in agreement with the initiator of the project. It is presented below:

• Appropriate template for a small poultry farmer;

• Cost of production close to 180,000 CFA francs;

• Produce an average of 300 chicks at each brood;

• Yield significantly better 85 to 95% ;

• This equipment must have ease of implementation, ease of operation and ease of maintenance;

• Uses the electric current as a source of energy.

Functions identification: The identification of functions is very important in a design process. In fact, the functions reflect, on the one hand, the description of the need to be fulfilled by the system and, on the other hand, they provide guidance for the choice of the different scenarios to be analyzed. The system is therefore considered as an arrangement of functions and not as an assembly of solutions.

To define the functions of our system, we use the representation tool called "octopus diagram". This diagram represents the system surrounded by external elements in contact with it. Whenever the system allows to put in relationship two elements of the external environment, there is service rendered. So, taking all the elements of the external environment 2 by 2, whenever it is possible to express a service rendered, there is a principal function (F). Whenever an element of the external environment exerts or undergoes an action of the system, there is a function of constraint (C). To define the functions of our system, we use the representation tool called "octopus diagram". This diagram represents the system surrounded by external elements in contact with it. Whenever the system allows to put in relationship two elements of the external environment, there is service rendered. So, taking all the elements of the external environment 2 by 2, whenever it is possible to express a service rendered, there is a principal function (F). Whenever an element of the external environment exerts or undergoes an action of the system, there is a function of constraint (C).The typical header is given by the following Figure 4:

This part presents the results of the work that was not possible thanks not only to the specifications that will be expressed as a technical service of the equipment.

The choice of elements is not random but by a key step that is sizing. It will undoubtedly allow us to avoid an exaggerated under-dimensioning or oversizing of our system but will allow us to obtain equipment composed of the adequate elements.

Dimensioning of the box and its elements

Dimensions de box:

Height: We will go of the average height of an egg, of the equipment to install in the incubator, to finally have the total height of the incubator.

• Average height of the egg: 0.065 meters;

• Height of two cells loaded (rack): 0.1 meters;

• Fan height: 0.12 meters;

• Height between two shelves: 0.12 meters;

• Height between the base and the first shelf: 0.15 meters;

• Height between the ceiling and the last shelf: 0.15 meter;

• Thickness of the wood: 0,02X2 meters;

• Thickness of the air layer: 0.01 meters;

• The thickness of the polystyrene is calculated as follows: (0.05 meter);

• Height control equipment area: 0.15 meters.

The total height of the incubator is 1.20 meters;

The height of all surfaces connected to the incubator is 0.95 meters;

Dimensioning of wood and polystyrene thicknesses

Thickness of the wood: The constraints of the market impose a thickness of wood to 20 millimeters maximum. This leads us to the design of expanded polystyrene.

Thickness of expanded polystyrene: We will start from the fact that the heat flux exchanged tends towards zero without being null, imposing us a surface of 1 square meter.

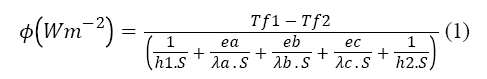

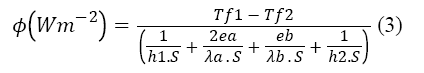

This formula follows from the diagrams below (Figure 5):

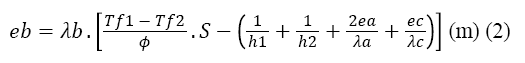

Hence the expression of the thickness of polystyrene:

where, Tf1: fluid temperature1 (air at 25°C);

Tf2: fluid temperature2 (hot air at 38 ° C);

S: lateral surface sides and rear face 1X1m = 01m2;

h1 (Wm-2K-1): natural convection heat transfer coefficient (air) "5";

h2 (Wm-2K-1): coefficient of heat transfer by forced convection (of air) "10";

λa (Wm-1 ° C-1): thermal conductivity of Okoumé plywood "0,12";

λb (Wm-1 ° C-1): thermal conductivity of "0.027" polystyrene;

λc (Wm-1 ° C-1): thermal conductivity of air "0.026";

ea: wood thickness. 0.02m;

ec: air layer, 0,01m

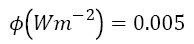

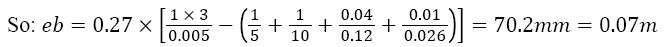

Imposing a flow;

Which leads to 7 centimeters thick polystyrene. But we will take 5centimeters because the heat exchange surface is less than 1 square meter.

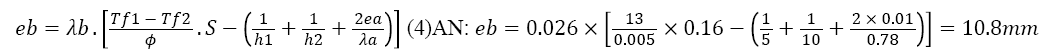

Air layer thickness

For the glazed side we will have:

S: glass surface 0,16m2

λ glass - 0,78

ea: glass thickness 0.01; this value has been imposed on us by the market.

Let’s keep the same flow exchanged by all the faces of the incubator, determine the thickness of the air layer between the glass planes (Figure 6).

The flow expression will be:

We deduce the thickness:

The thickness of the air layer between the two glass planes is 1 centimeter.

Width of the box seen from the side: We will start from the average width of the equipment to be installed in the incubator.

• Wood thickness plus insulating layers: 0,1meter;

• Space between the rear bottom of the incubator and the shelves: 0,15meter;

• Space front end of the incubator and shelves: 0.1meter;

• Door thickness : 0.03m ;

• Shelf width : 0.37meters ;

• The width of the crate seen from the side is 0.75 meters.

The width of the box seen from the front: This value is conditioned by the number of grids that each shelf will carry; we will have 2 brackets per shelf, including 60 eggs.

• Length of a grid (cell): 0.3 meters;

• Thickness of wood and insulating layers: 0.1x2meters;

• Security space: 0.1 meter;

• What leads to is a front view width of the 0,9meter incubator.

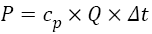

Dimensioning of the heating resistor: Heating is an operation that increases the temperature of the air without varying its absolute humidity. The calculation of the power can be performed:

By the temperatures:

With P the battery power (W),

• Cp: mass thermal capacity of the air (1005 J/kg AS/K),

• Q: mass flow (kg AS/s),

• Δt: difference in air temperature between the output and the battery inlet (K).

The thermal characteristics of the incubator are as follows:

• Thermal mass capacity of the air 1 005 J/kg AS/K;

• Mass flow (kg AS/s) about 0.025Kg / s of fresh air;

• A temperature difference of the air between the exit and the entrance of the incubator; That is a temperature of approximately 25°C (entry), and 38°C (exit) of which 13°C of difference

• From where P = 1005 X 0.025 X 13 = 326 W

By this value, we choose a resistance of 300W because this value is marketed.

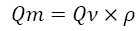

Dimensioning of the ventilation system: The air is set in motion by the fan. As the temperature of the air is modified by the heating resistance, the density of the air is different at each point of the incubator. By the law of conservation of the mass, the mass flow remains constant. Thus, it is the volumetric flow that varies along the incubator.

The mass flow is determined at the fan from the volume flow and the density:

: With Qm mass flow (kg/s),

: With Qm mass flow (kg/s),

Qv volume flow rate (m3/s),

Ρ density (kg/m3).

At a given rotation speed, the fan supplies a flow rate Qv and a total pressure difference Dp according to its flow/ pressure characteristic curve.

The fans are classified according to their mass work Wm;

Work volume corresponds to:

With Wv work volume (J / m3); ρ density (kg / m3); Mass work (J/kg).

The unit used to express Wv has the same dimension as a pressure. The working volume useful therefore corresponds to the total pressure created by the fan. The fans are distributed in low, medium and high pressure (Table 1).

| Type | Mass work(J/kg) | Pressure creates for a density of the order of the order of 1,2 kg/m3 (Pa) |

|---|---|---|

| Low pressure | 600 | 740 |

| Medium pressure | 600 à 3000 | 740 à 3600 |

| High pressure | >3000 | 3600 |

Table 1: Classification of fans.

Statement of need and identification of the functions of the incubator, Statement of the need of the incubator: The statement of need will be made briefly by the Horned Beast tool shown below (Figure 7).

Identification of functions (octopus diagram): Knowing the need previously stated by the beast tool and taking into account the specifications of the design objective, we build the octopus diagram of the system in the figure below (Figure 8).

From this Octopus diagram we release the following service functions:

FC: Constraint function

FC1: Produces heat energy through the heating resistor and ensures temperature homogeneity.

FC2: commissioning by the user (the poultry farmer).

FC3: Adapting to the environment

FC4: Easy acquisition for poultry farmers.

FC5: To manufacture on the scale of a small production.

FP: Main function

FP1: Produce day-old chicks (hatching eggs).

Analyze of technical functions: From the statement of need, from the identification of the functions and requirements of the CdCF, we highlight the technical functions, actions or technological objects that can be used to fulfill these different functions (Table 2).

| Service functions | Technical functions | Constructive solutions |

|---|---|---|

| F1 | FT1 : heating function | Heating element, Incandescent lamps, Hotplate |

| F2 | FT2 : brewing function | Fan |

| F3 | FT3 : temperature control function, switching on, tripping | Electronic thermostat, Analog thermostat |

| F4 | FT4 : humidification function | Water tank, spray, |

| F5 | FT5 : lighting function | Incandescent lamp, economic tube, Fluorescent tube |

| F6 | FT6 : storage function | Case of incubator |

| F7 | FT7 : thermal insulation function | Expanded polystyrene, Extruded polystyrene, Rigid foam, Cotton |

Table 2: Technical functions of the system.

Presentation of the incubator realized:

Figure 9: Side view of the incubator.

Figure 10: Rear view of the incubator.

This work consisted of designing an artificial incubator that should be used by poultry farmers in their own production of chicks. The interest of this incubator lies in the fact that it allows the poultry farmers who use it to increase their yield, reduce their expenses and their total dependence on the exclusive delivery of chicks of the objective of maintaining the internal heating temperature of the incubator has been achieved (Figures 9 and 10). Indeed, when the heating resistance of the incubator produces energy, the ventilator by the continuous stirring of the hot air homogenizes the temperature in the enclosure, the regulation of this temperature being ensured by the thermostat because when the temperature exceeds the 37,5°, it cuts the power supply of the heating fan and the indicator light of the control panel is extinguished. If under any influence the temperature of the chamber is raised above 39°C, the thermostat by its contact feeds the second fan, which in its position blows a little cold air, which allows, therefore, maintenance of the internal temperature of the incubator.

To achieve the establishment of this incubator, we opted for the design method based on functional analysis that led us to set up an incubator based on the principle of the production of heat by a heating resistor, which is essential. This work was done taking into account the ease of realization and acquisition of spare parts, building materials and can be evaluated at 318.35 USD, a cost accessible to small poultry farmers.

Although time has not allowed us to evaluate the efficiency and cost of the electricity consumption of the incubator, we have proposed to the NGO ORFED officials to produce a fully automatic prototype of a capacity in the near future 500 eggs.

This project is economically viable: the construction of this incubator requires equipment that is easy to find on the site. There is thus a considerable gain compared to the cases where the inputs allowing its manufacture have been imported.

In short, setting up such an incubator can contribute to the fight against poverty, while ensuring the transfer of technology.

We cordially thank your newspaper which offers us the possibility of being able to make known to the world, the fruit of our researches thus being able to contribute to the technological advancement.